Jason Bramwell — March 1, 2013

Bohn’s Farm and Greenhouses Inc. has successfully used sustainable plant production practices throughout its history-first as a vegetable grower and now as a wholesale grower of hardy herbaceous perennials.

As a young man working at Maryville, Ill.-based Bohn’s Farm and Greenhouses Inc. in the 1980s, Gary Bohn didn’t understand why his father and then-owner Walter Bohn cared so much about sustainable stormwater reclamation and recycled irrigation water management. Now, as the president of Bohn’s Farm, Gary understands.

Click image to enlarge.

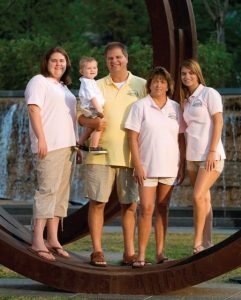

Gary Bohn, president of Bohn’s Farm and Greenhouses Inc., Maryville, Ill., is joined by (from left to right) his oldest daughter, Sarah, his grandson, Owen, his wife, Renee, and his youngest daughter, Elizabeth, at Citygarden in St. Louis. Bohn’s Farm provided $90,000 worth of custom-grown perennials for the urban park and sculpture garden.

Photos courtesy of Margy Terpstra, Bohn’s Farm and Greenhouses Inc. unless otherwise noted.

“He’s always been a big promoter of sustainability. He served on the Illinois Soil and Water Conservation District Board for 12 years,” Gary Bohn says about his dad, who is now vice president of the family’s business. “Because of his vision, we don’t have one drop of water runoff leave our property. One hundred percent of rainfall and irrigation water is captured in a central collection pond.”

From no-tilling corn and soybeans as a vegetable farm in the 1960s to reducing the amount of peat moss in its growing mix as a wholesale perennial grower today, sustainable growing practices have always been a hallmark of Bohn’s Farm.

Click image to enlarge.

A crew from Bohn’s Farm and Greenhouses Inc. works in one of the wholesale nursery’s production hoop houses. Bohn’s Farm has 5.2 acres of covered greenhouses and 3.5 acres of outdoor growing areas on 15 total acres.

Those practices also played a role in Bohn’s Farm custom growing more than 50 varieties of hardy herbaceous perennials for the Sustainable Sites Initiative (SITES) pilot project at the global headquarters of Novus International Inc., in St. Charles, Mo. The landscape restoration project was certified by SITES and received the highest rating among the more than 150 pilot projects worldwide.

“I think it’s important to try to do your part as a grower to be as green as possible and to save the planet for the next generation,” Bohn says.

From veggies to perennials

Bohn’s Farm was founded in 1931 by Gary’s grandfather, Anton Bohn, who bought land in Maryville and started a vegetable truck farm, according to Gary Bohn. When Anton died in the late 1950s, his son, Walter, took over the farm.

Click image to enlarge.

A cart of perennials at Bohn’s Farm and Greenhouses Inc. is ready to be shipped. Bohn’s Farm’s customers are located in parts of Illinois, Indiana, Kansas, Missouri and Nebraska.

“When I got in the business after I graduated from high school in 1976, we were growing 140 acres of fresh vegetables, such as tomatoes, asparagus, sweet potatoes and peppers, and about 900 acres of corn, soybeans and wheat,” Gary Bohn says.

Neighboring Collinsville, Ill., is the self-proclaimed “Horseradish Capital of the World,” and the Bohn family grew and sold the popular perennial plant. “I still raise tissue culture horseradish,” Bohn says. “Southern Illinois University in Carbondale has been researching and crossing new varieties of horseradish. I take the university’s new varieties and propagate them. We’ll have about 47,000 plugs of horseradish this spring.”

Because his four brothers did not have an interest in the family business, Gary worked long hours alongside his dad. “We would head out at 5:30 every morning and harvest sweet corn. It would then be bagged up and shipped out by 8:30 a.m. or 9 a.m.,” he says. “Then I would go to the horseradish field or the tomato field. My dad would take a crew and go here, and I would take a crew and go there.”

Bohn’s Farm’s biggest produce customers were the three grocery chain stores in the area: Dierbergs, Schnucks and Shop N Save. “Our relationship with Shop N Save was the longest because we also sold them perennials,” Bohn says. “Unfortunately, Home Depot and Wal-Mart pushed them out of the plant business.”

Bohn’s Farm Sustainable Plant Production Self-Analysis

The following are the eight Sustainable Sites Initiative criteria for sustainable plant production and how Bohn’s Farm and Greenhouses Inc., Maryville, Ill., met or exceeded those guidelines.

Use sustainable soil amendments, including peat-free media. Bohn’s Farm reduced the amount of peat moss in its growing media from 30 percent to about 8 percent, and the nursery is currently working with St. Louis Composting to completely eliminate peat moss from its mix.

Reduce runoff from irrigation; capture and recycle all irrigation runoff water on-site. The original layout of Bohn’s Farm’s 15-acre production nursery recognized the benefits of capturing 100 percent of rainfall and irrigation water in a 5.5-acre irrigation pond. This was accomplished by establishing adequate grades and slopes, as well as installing a network of solid and perforated drain pipe, to carry the water to the pond.

Irrigation tests also were completed before and after greenhouses were filled with plant material, which helped establish optimum irrigation time cycles to limit water use and energy to operate the system.

Reduce greenhouse gas emissions; use on-site renewable energy sources to meet 10 percent of electricity demands. Bohn’s Farm’s production practices require only 12,000 square feet of supplemental, heat-equipped covered greenhouse space among a total covered greenhouse space of 211,500 square feet. The remainder of its production space is outdoors and noncovered.

Only during extreme cold temperature periods is supplemental heat – using natural gas – provided for winter-tender crops, which are located in limited portions of nonheated covered greenhouse space.

Reduce energy consumption; demonstrate that energy use during the three most recent years is at least 25 percent less than the average energy use over the previous 10 years. Natural gas use by Bohn’s Farm’s heat-equipped greenhouses has decreased in recent years, partly due to heat being used when absolutely necessary.

For example, in the 2009-10 fiscal year, the nursery used 8,490 therms, down from the 14,875 therms it used in the 2000-01 fiscal year. The nursery’s 10- year average was 13,145 therms. Bohn’s Farm also reduced electricity use, from 104,896 kilowatt hours (kWh) in the 2000-01 fiscal year to 77,470 kWh in the 2009-10 fiscal year. The 10-year average was 94,828 kWh.

Use integrated pest management (IPM). IPM practices maintain the quality of the recycled irrigation water at Bohn’s Farm. Vegetation-control methods, such as manual removal and controlled glyphosate application, are used to reduce vector activity within and along the perimeter of the nursery. Insect and disease pest management is managed on a case-by-case basis, and no broad spectrum or routine pesticide applications are used.

Reduce use of potable water; use nonpotable water for 70 percent of irrigation volume. All greenhouses and outdoor production areas at Bohn’s Farm are irrigated with nonpotable water from its site collection pond. Bohn’s Farm’s nonpotable water source receives stormwater runoff from 44 rural/suburban acreage, including all 15 acres of the nursery’s production facility.

Reduce waste; conduct a waste audit to identify the weight or volume of ongoing consumables and reuse, recycle or compost 50 percent of the ongoing consumable waste stream. Local and regional material recycling vendors are regularly used by Bohn’s Farm to recycle all cardboard, odd-lots and damaged horticultural plastic containers (three truck loads ranging between 5,000 and 8,000 pounds per load), scrap steel and aluminum, and tires.

Bohn’s Farm also has an inventory of used plastic pots that are reused for production of grown crops for landscape contractors. For example, in 2010, the nursery reused more than 8,000 1-quart pots, 52,000 No. 1 pots and more than 12,000 No. 2 pots for contract-grown perennials.

Recycle organic matter; compost and/or recycle 100 percent of vegetation trimmings on-site for use in nursery operations or for sale to the public. All organic waste generated by Bohn’s Farm’s production operations, including vegetation trimmings and growing media contents of nonsaleable production, is composted on-site. The resulting compost material is then distributed with a manure spreader and incorporated with the soil at the nursery’s adjacent agronomic cropland.

One of Bohn’s earliest memories is of his dad using sustainable practices for growing pumpkins. “He was planting pumpkin plants in the freshly harvested wheat fields. That way the pumpkins could sit on the straw and not be muddy, and the weeds would not be an issue because the straw was there to buffer the ground from the moisture,” he says. “In the 1960s, he was no-tilling corn and soybeans. He was always big on soil and water conservation.”

As more subdivisions and commercial businesses sprang up around the St. Louis area in the 1980s, and as wholesale market demand for locally produced vegetables declined, the Bohn family decided to explore production of ornamental horticulture crops.

“I don’t think my dad and mom really wanted to go that route, but we really had no other choice to keep the farm running,” Bohn says. “The 80 acres of farmland where we grew all of our horseradish and sweet corn is hotels, a convention center and restaurants now. We only have 42 acres left on the family farm.”

In 1985, Walter and Gary built their first greenhouse to grow vegetable plants and flowering annuals for local garden centers and produce retailers. “We also grew bedding plants for a couple park districts in the area, and we always had pick-your-own strawberries,” Bohn says. “I also grew some perennials for my wife’s brother, who owned a small landscaping company.”

One day in the early 1990s, Gary was visited by Bill Ruppert, a sales representative for Zeeland, Mich.-based Walters Gardens Inc. Ruppert also manages the St. Louis office of National Nursery Products, a horticultural sales, marketing and consulting company that represents regional and national wholesale growers of ornamental and environmental landscape plants.

“Gary was a Walters customer, and I asked him, ‘Did you ever think about growing perennials on a wholesale level?’” Ruppert recalls. “Gary said he had thought about it, and I told him there weren’t many wholesale sources for finished perennials in the St. Louis area.”

“Ruppert suggested I start raising plants, and he would sell them,” Bohn adds. “It didn’t take us long to get out of the vegetable business and get into the greenhouse business.”

Of the 15 acres it uses for the wholesale nursery, Bohn’s Farm has 5.2 acres of covered greenhouses and 3.5 acres of outside growing areas. All irrigation water is captured in a central irrigation pond, which was expanded from 3 acres to 5.5 acres in 2008. A network of solid and perforated drainpipes was installed in the 1980s to carry the water to the pond.

“Our irrigation system uses a 40-horsepower, 6-inch pump that pumps 600 gallons of water a minute. On a normal day, we usually run two to two-and-a-half hours of water in the complex. All that water runs back to our lake source,” Bohn says.

Today, Gary, his wife, Renee, and their oldest daughter, Sarah Kolesa, oversee the nursery’s day-to-day operations. Bohn’s Farm has 15 full-time employees, who have worked at the nursery for almost 16 years. Gary adds between six and eight part-time workers in April and May to help ship plants.

Click image to enlarge.

National Nursery Products provides sales support for Bohn’s Farm and has offices in Indiana, Kansas and Missouri. “We have a pretty ideal team,” says Ruppert, who heads up the St. Louis office. “Gary is all about production, and I’m all about selling production. We don’t get in each other’s way, and we all have our roles.”

Bohn’s Farm grows approximately 1,100 different varieties of hardy herbaceous perennials in quart, gallon, 2-gallon and 3-gallon containers, according to Bohn. He adds that the nursery’s customer base has changed drastically in the past 20 years.

“When we started growing perennials, 95 percent to 98 percent of our plants were sold to independent garden centers,” Bohn says. “Now, we’re 50 percent retail garden centers and 50 percent landscape contractors. I’m glad we began supplying to landscape professionals. I don’t know if we’d be around today if we were strictly relying on retail garden centers because their sales have dropped.”

Click image to enlarge.

The landscape at the global headquarters of Novus International Inc. near St. Louis was redesigned as part of a pilot project by the Sustainable Sites Initiative (SITES). SITES certified Novus with a three-star rating, making it the highest-rated landscaping project in the world.

While Proven Winners varieties from Walters Gardens and its own line of Tread and Trail groundcovers for pathways and borders have historically sold well, Bohn’s Farm has become one of the St. Louis area’s top growers of native plants for landscape contractors.

“We got into the native business eight or nine years ago. Back then, we grew 15 to 20 varieties of natives. This spring, we’ll have 142 varieties,” Bohn says. “Our best-selling natives include Andropogon gerardii (big bluestem), Echinacea purpurea (purple coneflower), Rudbeckia fulgida (black-eyed Susan), Sporobolus heterolepis (prairie dropseed) and Schizachyrium scoparium (little bluestem).”

SITES set high

Launched in 2005 as a partnership between the American Society of Landscape Architects, Lady Bird Johnson Wildlife Center and the U.S. Botanical Garden, SITES has established voluntary national guidelines and performance benchmarks for sustainable landscapes of all kinds – with or without buildings.

Modeled after the Leadership in Energy and Environmental Design (LEED) Green Building Rating System of the U.S. Green Building Council, SITES’s four-star rating system gives participating organizations credits for the sustainable use of water, the conservation of soils, wise choice of vegetation and minerals, and design that supports human health and well-being in their landscapes. Based on achieving all 15 of the program’s prerequisites and at least 100 credit points, the sustainable landscaping project becomes certified.

To put this rating system to the test, SITES launched a two-year international pilot program in 2010 that included more than 150 projects in 34 states, as well as in Canada, Iceland and Spain. The program included a diverse cross-section of project types, sizes and geographic locations in various stages of development, from design to construction and maintenance.

Feedback from the pilot program is being used to revise the final rating system and create a reference guide that will provide suggestions on how projects achieved the sustainability goals of specific credits. The guide is scheduled to be released later this year.

One of the participants in the pilot project was the global headquarters of Novus International, a leader in animal health and nutrition. SITES selected Novus because of its extensive environmentally friendly practices. In 2009, the U.S. Green Building Council awarded Novus with Platinum LEED certification, the highest designation available to buildings that demonstrate energy efficiency and sustainability.

Herbaceous Perennials Used at Novus International

Bohn’s Farm and Greenhouses Inc., Maryville, Ill., provided the following custom-grown herbaceous perennials for the Sustainable Sites Initiative pilot project at the global headquarters of Novus International Inc., St. Charles, Mo.

- Amsonia illustris (shining blue star)

- Amsonia tabernaemontana (blue star)

- Amsonia tabernaemontana ‘Short Stack’ (‘Short Stack’ dwarf blue star)

- Asclepias incarnata (swamp milkweed)

- Asclepias tuberosa (butterfly milkweed)

- Aster novae-angliae (New England aster)

- Aster oblongifolius (aromatic aster)

- Baptisia australis (blue false indigo)

- Baptisia sphaerocarpa (yellow wild indigo)

- Bouteloua curtipendula (sideoats grama)

- Calamagrostis acutiflora ‘Karl Foerster’ (‘Karl Foerster’ feather reed grass)

- Caltha palustris (marsh marigold)

- Carex annectens (yellow-fruited sedge)

- Carex buxbaumii (Buxbaum’s sedge)

- Carex muskingumensis (palm sedge)

- Carex pensylvanica (Pennsylvania sedge)

- Carex stricta (Tussock sedge)

- Carex vulpinoidea (fox sedge)

- Coreopsis lanceolata (lanceleaf coreopsis)

- Echinacea purpurea (purple coneflower)

- Equisetum hyemale (horsetail rush)

- Eupatorium dubium ‘Little Joe’ (‘Little Joe’ Joe Pye weed)

- Filipendula rubra (queen of the prairie)

- Helianthus occidentalis (western sunflower)

- Heliopsis helianthoides (oxeye sunflower)

- Hibiscus lasiocarpus (rose mallow)

- Hypericum calycinum (St. John’s wort)

- Iris virginica var. shrevei (southern blue flag)

- Juncus effusus (soft rush)

- Lobelia cardinalis (cardinal flower)

- Lobelia siphilitica (great blue lobelia)

- Mertensia virginica (Virginia bluebells)

- Mimulus ringens (monkey flower)

- Monarda fistulosa (wild bergamot)

- Panicum virgatum ‘Heavy Metal’ (‘Heavy Metal’ switchgrass)

- Peltandra virginica (green arrow arum)

- Penstemon cobaea (dew flower)

- Physostegia virginiana (obedient plant)

- Rudbeckia fulgida (black-eyed Susan)

- Rudbeckia subtomentosa (sweet coneflower)

- Sagittaria latifolia (broadleaf arrowhead)

- Salvia azurea (blue sage)

- Schizachyrium scoparium (little bluestem)

- Scirpus cyperinus (woolgrass)

- Sedum kamtschaticum (stonecrop)

- Solidago rugosa ‘Fireworks’ (‘Fireworks’ goldenrod)

- Sporobolus heterolepis (prairie dropseed)

- Stylophorum diphyllum (celandine poppy)

- Thalia dealbata (hardy canna)

- Zizia aurea (golden Alexander)

Novus selected SWT Design, a landscape architecture company in St. Louis that specializes in designing environmentally sensitive landscapes, to lead the project, and Landesign LLC, Wentzville, Mo., was chosen as the landscape contractor. SWT Design was looking for a wholesale nursery that could provide herbaceous perennials for the Novus project. Hunter Beckham, ASLA, SWT Design principal and Novus pilot project manager, contacted Ruppert, whom he had worked with previously on other landscaping projects.

“Hunter told me what they were doing, and it was the first time I had heard of SITES,” Ruppert says. “SWT Design was looking for input on plant selection, and it was looking to receive as many SITES credit points as possible. Some of those points come from the grower.”

In 2010, Bohn’s Farm conducted a self-analysis of its wholesale production plant business that showed SWT Design and SITES it met or exceeded the eight SITES criteria for sustainable practices in plant production (see sidebar, Page 5).

“Gary and I reported the sustainable production practices that Bohn’s Farm was already using. We didn’t really have to change anything,” Ruppert says. “The only thing that we’ve really pursued was reducing the amount of peat moss in our growing mix. We’re working with a wonderful company by the name of St. Louis Composting that has helped us reduce peat moss from 30 percent to between 5 percent and 10 percent. St. Louis Composting thinks we can eventually eliminate peat moss completely from our mix.”

The self-analysis was submitted to SWT Design, which included it as part of its final presentation of materials for the Novus pilot project to SITES. “We were told that we were the first grower in the country to submit a self-analysis of the eight SITES points for sustainable plant production, and Hunter told us SITES was going to use ours as a guideline in the future,” Bohn says.

Click image to enlarge.

Landscape architects from SWT Design transformed a previously barren and unfriendly looking retention pond at Novus International Inc. into an improved aquatic habitat with a pavilion for outdoor functions.

Bohn and Ruppert worked with SWT Design to create a plant palette for the Novus pilot project, and representatives from SWT Design and Novus visited the farm to inspect the herbaceous plant material before it was delivered to Landesign.

“That was the first time I’ve ever had a designer’s client come out to see the plant material. There was a lot of attention to detail,” Ruppert says. “The plants were roped off and kept in their own greenhouse so they were not commingled with all the other material. No other landscapers could go in that house.”

Bohn says $50,000 worth of custom-grown herbaceous perennials from Bohn’s Farm was used for the Novus landscape redevelopment (see sidebar, Page 28). “All herbaceous plants on the Novus site, whether plugs, quarts or gallons, came from Bohn’s Farm,” Ruppert adds.

The redevelopment of the 9-acre Novus campus landscape began in late 2010 and took approximately nine months to complete. Before the project started, Ruppert characterized the landscape as “the traditional corporate landscape, or what I like to call a mow, blow and go landscape.”

The Novus project addressed several sustainable design best practices, including hydrology, wildlife habitat enhancement and monitoring, improved soils and vegetation with an emphasis on using regional materials, and features that address human health and well-being of site visitors. Highlights of the new landscape include:

- A previously barren and unfriendly retention pond was transformed into an improved aquatic habitat. The area includes a pavilion for outdoor functions.

- Bioswales were planted with native vegetation to clean, filter and slow the flow of water that goes into storm drains. Rock walls and ledges were also built to slow the erosion of soil.

- Terraced gardens were planted with low-maintenance vegetable plants and herbs that are used by the Novus staff chef for employee lunches. Water for the plants is pumped from an underground well that is powered by an on-site wind turbine. Potable tap water is not used.

- Novus is working with partners from the St. Louis Zoo Department of Invertebrates to measure populations of native pollinators and other bugs that are on the site.

In late January 2013, the Novus pilot project became certified after SITES awarded it with a three-star rating (150 out of a possible 250 credit points), making it the highest-rated landscaping project in the world.

“The Novus project is definitely something Bohn’s Farm is very proud to have been a part of because it gave us a chance to learn more about how sustainable our plant production practices really are,” Ruppert says.

Jason Bramwell is a freelance writer, and a contributor to and former senior associate editor of American Nurseryman. He can be reached at [email protected].